-

Notifications

You must be signed in to change notification settings - Fork 11

04 Construction instructions

The important bit here is to cut the foam to the desired shape, then draw center lines along the length and width. This is very important for mounting the flight controller; the closer to the center, the better the accelerometer will function. You should also mark the lines along which the spars will be mounted. I put mine 2 inches in from the edge.

The spars must be long enough that the propellers have clearance over the foam fuselage. If they don't, then the propellers will lose lift. For example, for a set of 10x4.5 props, there should be a good 6-7 inches from the end of the spar to the foam. If not, then you may have to cut away some foam to make clearance. Once you've done this, you can mount the spars.

Measure and mark half the length of each spar. Slide two 3D printed T-mounts onto each spar and position them on the inside edge of the fuselage. Tighten the bolt just enough so they don't move. Take a large rubber band and hang it over one spar on the outside of one mount. Then pull it under the 'T' of both mounts and back over the spar on the other end. Mount the spar onto the fuselage and wrap the rubber band underneath to hold it. You can now tighten the rubber band by twisting one end over the T-mount until the spar is set solidly on the fuselage. Do this for the other spar as well.

Lastly, cut some upholstery foam or other foam, lift the spar mounts off the foam, and place them underneath. This will prevent vibration from the propellers from negatively affecting the flight controller.

Depending on which ESCs you buy, you probably need to solder connectors to them. The female XT-60 connector will be soldered to the black and red wires, which will in turn be connected to the power distribution lump (see below). Make sure you solder the right connection: red is +, black is -. Solder bullet connectors to the three wires on the other side of the ESCs. Make sure you cover all soldered connections with electrical tape or shrink tubing. Then you can connect the three ESC wires to the three wires on each motor. At this point it does not matter which wire goes where because later you will have to check the motor spin direction anyway.

The motor configuration for an H-shape copter is the same as that of a Quad X:

CW CCW

3 1

\ /

\ ^ / ^ APM facing forward ^

X

/ \

/ \

2 4

CCW CW

Attach motor mounts to each motor and slide them on to the end of each spar. Do not tighten the mount to the spar too tightly or it will break.

Here is a great diagram for connecting the wires in the APM. When connecting the motor/ESCs, you must connect the corresponding motor number to the number on the board. Once you have made the connections, you can mount the parts onto the quad.

First, place the flight controller in the exact center of the quad using the lines you marked earlier. The small arrow on the APM should face forward. Drawing an outline around the controller and set it aside. Push a screwdriver or rod through the foam on each side of the controller, then pass a rubber band through both holes so that a loop protrudes out of each hole underneath the quad. Something like a paperclip can be used to hold each loop. Now insert the flight controller back in place, held tightly by the rubber band. Use upholstery foam under the flight controller to prevent vibrations.

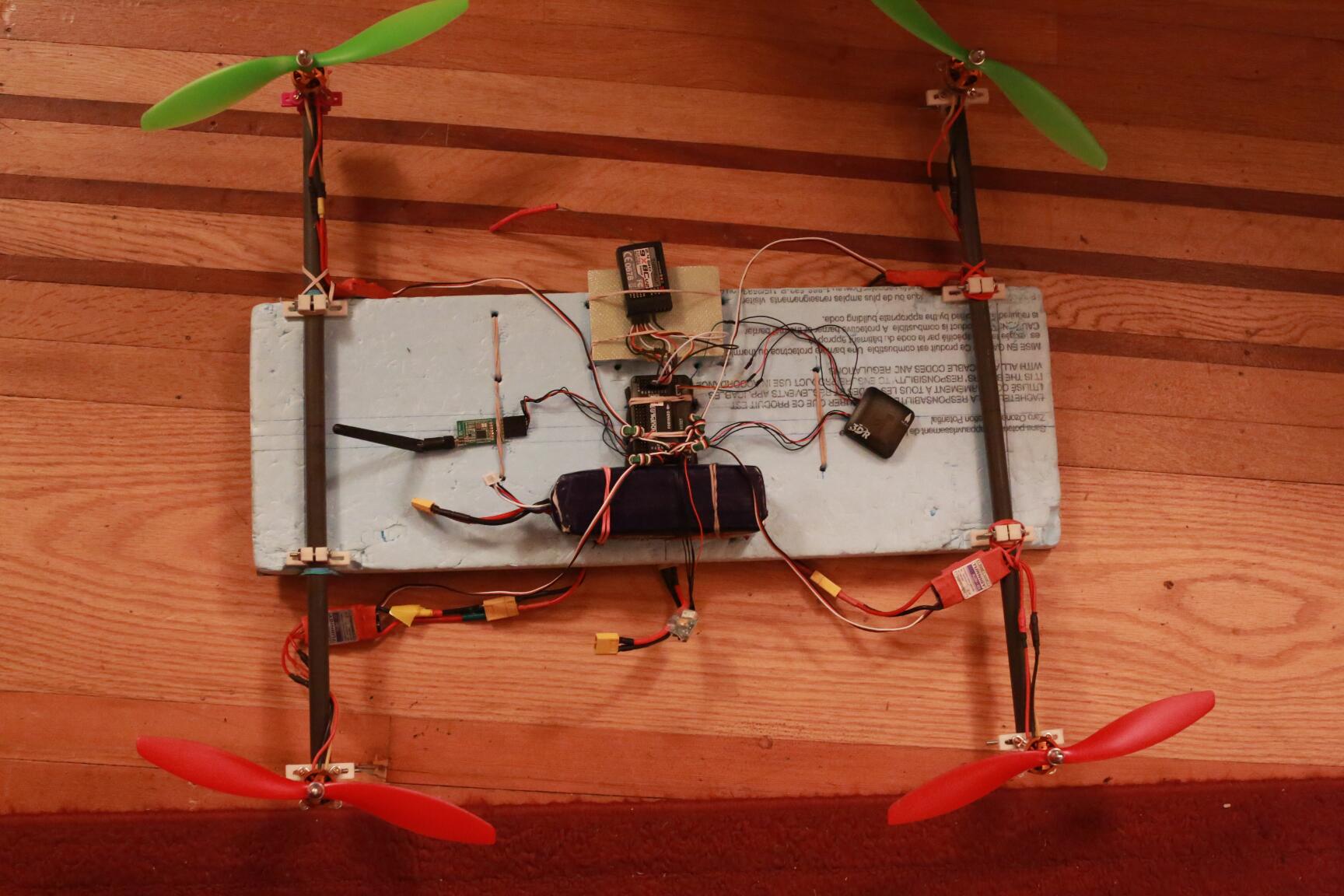

Use the same process to mount the receiver, telemetry, GPS, and battery in the following configuration:

You need to get power to, at a minimum, 4 speed controllers/motors and 1 power module (for the flight controller; included in the recommended flight controller kit). You also need to get power from the battery to these 5 elements. Therefore you need at least a 6-way power distribution setup; 1 in and 5 out. That means two star-shaped wire junctions, one for positive and one for negative.

We actually recommend adding a 7th set of wires, albeit very small ones, to power accessories like lights. These need not be the heavy 12-guage wire used for distributing power to the motors, wire the size of servo leads is more than sufficient.

You could buy one of these: http://hobbyking.com/hobbyking/store/uh_viewItem.asp?idProduct=23140 but it's just as easy to create your own, and as an added bonus it can have more than 4 outputs.

Take the red 12-guage wire you ordered, and cut 6 pieces: 1 X 15cm - for the battery 1 X 20cm - for the power module 4 X 30cm - for the motors (should be more than needed; you can trim these to the perfect length later)

Get some "blu-tack" or other putty. Place four blobs on a flat, clean surface, in a square about 10cm on a side. Then add two more blobs on the diagonal, for a total of six. Now place your 4 motor wires in a + pattern, touching in the middle and held down by the first four blobs of putty (the square). Add your power module and battery wires on the diagonal, also touching the central point.

You should now have 6 wires, all held firmly by putty, touching in the centre. Grab a soldering iron, and heat them all up, and then apply some solder. You should end up with something that looks like a nice shiny star in the centre of the wires; try to make sure that all wires are nicely "wetted" with solder (you might have to turn the whole assembly over, like flipping a pancake, to thoroughly wet all wires).

We recommend then adding another, small (servo-lead size) wire to the star (you should be able to add this by hand). That will be useful for other bits, like a camera gimbal, some LED lights, or whatever.

Wrap the star up with electrical tape, making sure there's no exposed wire or solder, and then make another one with the black wires!